charpy impact test results stainless steel|charpy impact test specimen size : inc The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .

WEB00:00. Hayley Davies & Kelsie Monroe w Jmac threesome. Subscribe. 26 579. Published by. king6463. 6 months ago 13 114 32min 37sec. 96% (33 votes) Download.

{plog:ftitle_list}

15.03.2024. Santos/SP. Eletrônica. Vintage Culture, Amémé, Antdot, Blond:Ish, Mathame, Mochakk, Victor Lou. Festas, Navios. Comprar Ingressos. Cupom já inserido. CUPOM TIMELAPSE ESTÁ ATIVO – .

hi guys, may i need the help regarding to impact test for stainless steel A182 Gr316, the input is code construction ASME B31.3, design temperature is -90 to 100 degree C. .Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

The INL developed a drop-weight impact testing machine (ITM) to begin the consideration of these variables and determine strain rate elevated true stress-strain curves for stainless steel .In this investigation, we performed instrumented Charpy tests in order to characterize the impact properties of three steels, used by NIST for the production of Charpy reference specimens .Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .

The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

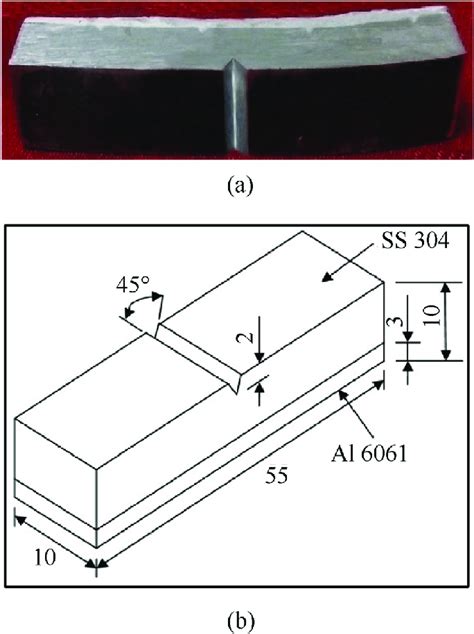

charpy test sample dimensions

flir methane detection

Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. The use of materials that do not meet the requirements can have fatal consequences. When coldness and strong force Charpy impact tests were performed on mild steels with body-centered cubic (BCC) crystal structures for comparison with the test results of welded austenitic stainless steels with face-centered .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .The testing machine is in conformity with the international GB/T3803-2002 Testing of Pendulum Impact Testing Machine, and the impact test for metal materials is carried out according to international GB/T229-2007 Metal Charpy Notch Impact Test Method.Since fracture or failure behavior depends on temperature, Charpy impact tests are often performed in the entire operating temperature range. This shows at what temperature and to what extent the material becomes brittle (tough-to-brittle transition).. The example diagram shows that the decrease in strength of mild steel at -40 °C is 25 % in relation to the strength at 0 °C.

316L stainless steel is a promising material candidate for a hydrogen containment system. However, when in contact with hydrogen, the material could be degraded by hydrogen embrittlement (HE). Moreover, the mechanism and the effect of HE on 316L stainless steel have not been clearly studied. This study investigated the effect of hydrogen exposure .The results obtained during the Tensile test, Charpy Impact test, Rockwell Hardness test, Microstructure and Percentage Shear Area of 316L stainless steel before and after cryogenic test are illustrated and discussed below : 3.1 Tensile Strength Fig.5. Tensile Test Results. The Ultimate Tensile Strength and Yield strength

methane meter

impact testing machine the charpy ‘V’- notch impact test was carried out for weld metal. Gas tungsten arc welded joints using duplex stainless steel filler metal has higher charpy impact toughness values compared with the gas tungsten arc welded joints using austenitic stainless steel filler metals. The toughness value of In this study, an austenitic stainless steel pipe for the transportation of liquefied natural gas (LNG) was gas tungsten arc welded with a wall thickness of 15.1 mm. Low-temperature Charpy V-notch (CVN) impact tests were performed to investigate the effect of low temperatures on the fracture toughness of the welded zone (WZ), heat-affected zone (HAZ), .Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Charpy V-notch (CVN) impact tests were conducted at ambient and low temperatures to study the effect of HE on the impact properties and fracture toughness of 316L stainless steel under the tested .

Charpy V notch (CVN) impact testing was conducted on full size and subsize specimens of sintered and wrought 17–4 PH stainless steel (17–4 PH SS) in the as sintered and H900 heat treated conditions. Test geometries correspond to the American Society for Testing and Materials (ASTM) and Metal Powder Industries Federation (MPIF) impact .Download Table | Charpy test results (Charpy impact energy). from publication: Study of Resistance Spot Welding Between AISI 301 Stainless Steel and AISI 1020 Carbon Steel Dissimilar Alloys .

The most widely used test of impact toughness is the Charpy test. A notched specimen is struck by a weighted pendulum, and the energy absorbed during impact recorded. Results are typically taken in triplicate, to limit the potential variability of this test method and the testing is undertaken at a specific temperature often related to the alloy.The results thus presented show the effect of the temperature on the ductile behavior of material. See full PDF download Download PDF. . Keywords: Impact, Charpy Test, Stainless Steel 316L, Temperature, Tenacity. 1. . Charpy impact test. The charpy impact and toughness properties of the tow-welded joint prepared with type ER316LN and ER308LN austenitic stainless steel filler metals have been compared. The results .

The results thus presented show the effect of the temperature on the ductile behavior of material. Keywords: Impact, Charpy Test, Stainless Steel 316L, Temperature, Tenacity. 1. IntroductionThe Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results. The Charpy test specimen are used where the influence of the angle and the depth of the notch were studied. . which raises higher demands on the excellent impact toughness of stainless steel . deposits shall be impact tested in accordance with para. 323.3. • When impact testing is required by Table 323.2.2, paragraph 323.3.4 and sub-paragraphs require Charpy impact testing at a temperature not higher than the design minimum temperature. Note: Section VIII Division 1, UHA -51(a)(3) only requires impact testing at - 320°F

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

The temperature dependence of the Charpy impact energy of the SA508Gr.4N steel is shown in Fig. 4. The Charpy energy curves can be divided into three regions corresponding to the: upper shelf .

In this paper, instrumented tension-impact (dynamic tensile) and instrumented Charpy impact test results for AISI 308 stainless steel welds at room temperature are reported.

The plastic behavior of the 17-4 PH stainless steel casting was evaluated using standard tensile, compression and Charpy (blunt V-notch and fatigue precracked) test procedures. Fiqure 2 illustrates the location of these samples as removed from .How to Use Charpy Impact Test Results. Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its intended use. 1. Energy Absorption

In this paper, instrumented tension-impact (dynamic tensile) and instrumented Charpy impact test results for AISI 308 stainless steel welds at room temperature are reported. A few Charpy specimens precracked to a/W (crack length to width ratio) ratios of 0.42 to 0.59 were also tested. Dynamic yield strength obtained from tension-impact test agrees well with that from Charpy .

charpy impact test standard pdf

h2 gas analyzer

webOur free Ask AI Answer Engine enables users to ask questions in a natural language and receive detailed, accurate responses that address their exact queries, making it an excellent alternative to ChatGPT.

charpy impact test results stainless steel|charpy impact test specimen size